Country Reports

ITALY

Luca Benedetti and Matteo Gianni

Gestore dei Servizi Energetici - GSE

RESEARCH & DEVELOPMENT

All the actors from the private and academic sectors that were already included in the 2017 Report are actively involved in R&D activities to further improve their devices, increase their technology readiness level (TRL) and lower their levelized cost of electricity (LCoE). Here we only present cases of substantial upgrade and relatively high TRL.

RESEARCH INFRASTRUCTURES

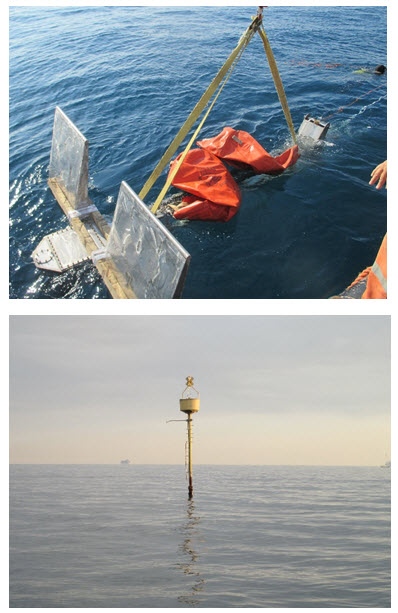

- Design and installation of the SeaPower Natural Laboratory in Vialla San Govanni (RC)

The University of Naples “Federico II” has a long-standing experience in the design and testing of tidal energy converters. The university spin-off SeaPower scrl, a non-profit private consortium that already patented new marine energy converters, is now bound to implant a natural laboratory offshore Villa San Giovanni (RC), for the development, optimization and monitoring of innovative devices for the exploitation of tidal currents. Its location in the Strait of Messina is ideal for the significant intensity of local currents and the extremely favourable climatic conditions offered throughout the year, two requirements that are rarely simultaneously met in the Mediterranean Sea. The authorization process for the construction of the laboratory is in progress: the Environmental Impact Authorization has already been granted and the detailed project for the onshore infrastructures has been submitted to the Ufficio del Genio Civile OO.MM. (Civil Engineering Department, Coastal Operations). The official permission for building is expected to be granted soon by the Municipality of Villa San Giovanni, and to be immediately followed by the necessary Public Maritime Domain concession.

Due to the peculiar hydraulic characteristics of its location (Punta Pezzo), the SeaPower laboratory will represent a unique facility in the Mediterranean, offering the opportunity to test both full scale and reduced scale prototypes in a fully monitored natural environment. The laboratory will consist of five areas, permanently designated for the monitoring and testing of prototypal turbines, of a test area on the existing artificial pier and of an onshore laboratory to host the related infrastructure assets. An additional artificial breakwater will be built in the proximity of the marine test areas for logistic support to operations at sea. Submerged cables will connect the converters at sea and the monitoring equipment to a submarine hub, from which a single cable will carry both the electric current produced and the acquired data to the onshore lab.

INNOVATIVE CONVERTERS

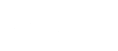

- PIVOT Wave Converter (TRL 5)

The PIVOT system is a Wave Energy Converter (WEC) that consists in a hinged floating body oscillating under the effect of wave motion and an electric generator, connected via high-tech components. It has been developed from the GEL prototype by Seapower scarl in collaboration with the University of Naples “Federico II”. The shape and inertial characteristics of the floating body have been specifically designed, as well as the structure that fastens it to the rotating axis connected to Power Take-Off (PTO) system.

The conversion of mechanical energy can be achieved through a variety of technical solutions. The PTO currently consists of an electric generator coupled to a recirculating-ball screw that was designed in collaboration with the manufacturer, Umbra Group Spa. The PTO is connected both to the oscillating body (via a piston and a hinge) and to the fixed structure. Wave motion forces the system to oscillate and induces the consequent rotation of its hinged axis, which results in the linear oscillation of the piston that is finally transmitted to the generator via the recirculating-ball screw. Both reduced scale and full scale prototypes of the system have been tank tested, reaching TRL 5. Testing in real sea conditions was scheduled for December 2018, when a full scale PIVOT prototype using the described system configuration was to be anchored onto a breakwater in the port of Civitavecchia (Roma).

The PIVOT full-scale prototype (5 m width), in the wave tank of University of Naples “Federico II”

The PIVOT full-scale prototype (5 m width), in the wave tank of University of Naples “Federico II”

The PIVOT concept can be exploited in different configurations, by using alternative PTOs or by adapting the mobile and fixed structures to specific requirements. In particular, a system based on an oscillating floating body is currently under development, in which the mechanical transmission of motion to the generator is achieved via an innovative system that reduces the criticalities deriving from the alternating wave-induced motion.

The new configuration will be designed for both offshore and onshore installation, so as to expand the range of its possible uses, and to minimize the risk of disruption from extreme waves to which onshore plants are exposed. Future activities are expected to bring the PIVOT system to a higher TRL.

-

The E-WAVE 100 converter (TRL 4) for near-shore installation The E-WAVE 100 converter model

The E-WAVE 100 converter model

The E-WAVE 100 converter consists of a dual chamber Oscillating Water Column (OWC) device, designed for being integrated into vertical wall breakwaters. The two chambers that constitute the device act in charge/discharge mode respectively, and are both equipped with specifically adapted non-return valves. In particular, wave motion causes sea water to rise to a level higher than the external mean sea level in the first chamber, which is equipped with free-flow valves allowing the free passage of the inward flux. Inside the second chamber, in its turn equipped with free-flow valves allowing the free passage of the outward flow, the water level is lower than the external mean sea level, and the resulting hydraulic potential generates the water flow in the duct that connects the two chambers. Electro-mechanic conversion is achieved via a low-head hydraulic turbine.

The E-WAVE 100 converter is characterized by minimum installation costs, low maintenance costs, scalability and modularity, as its simple structure can be constructed by using commercial components and materials that are easily available.

A reduced scale (1:20) model was tested in the Aalborg University tank in 2017, while in 2018 the 1:2 model was tank tested in the Large Wave Flume (GWK) of Hannover University, in the context of the MARINET2 EU project.

- The IMPETUS-UNIPA device (TRL 4) for near-shore installation

The IMPETUS-UNIPA device was developed and patented by the Department of Energy, Information Engineering and Mathematical Models (Dipartimento Energia, Ingegneria dell'Informazione e Modelli Matematici - DEIM) of the University of Palermo. It is a point absorber that consists in a cylindrical body containing a linear electric generator. The stator is integrated into an inner cylinder while the rotor is connected to an external cylinder that moves along with vertical wave motion.

The PM electric generator is an innovative device used to convert mechanical energy into electricity. This new technology offers the advantage of being free from any polluting additives, and can therefore be considered to be completely “clean”.

- The ECOMar 100 wave energy converter (TRL 4) for near-shore installation

The ECOMar system by Kuma Energy is a Wave Energy Converter that can be integrated into any vertical structure and installed on any seabed. It is modular and can be upscaled from installation of a few KWh (e.g. small touristic harbours) to very large plants. ECOMar is a versatile hybrid system that combines a hydraulic and an electromagnetic converter, allowing energy production at both low and high frequency and for different wavelengths. It integrates a system for environmental monitoring, in order to automatically be switched off in case of extreme sea conditions, and is designed to be completely harmless for vessels adrift, as its floating body acts as a robust fender. ECOMar can be easily equipped with a system for the collection of plastic or other floating waste.

The ECOMar system is comparatively low cost, as it uses standard components that are easily available on the market, and it is designed to also minimize management and maintenance costs. A 1:8 prototype has been tank tested in the AM3 spin-off laboratory of the University of Florence, while a pilot plant is under development.

The ECOMar 100 wave prototype

The ECOMar 100 wave prototype

-

The SEASPOON device for off-shore applications (TRL5) The SEASPOON device

The SEASPOON device

Seaspoon is an innovative submerged device designed for offshore applications. The system exploits the orbital trajectories of near-surface seawater motion, by automatically aligning its rotation axis with that of the orbit, perpendicular to that of wave propagation. Its depth can be modified according to the projected wave energy density, a characteristic that also allows protecting the device in case of extreme sea conditions.

The Seaspoon was patented by the Thermochemical Power Group (TPG), a spin-off of the Technical University of Genoa) (Italian patent 1405004 GE2011A000020), after being tested in real sea conditions offshore Genoa. Future activities include the improvement of the electric generator, and are expected to bring the device to TRL 6-7.